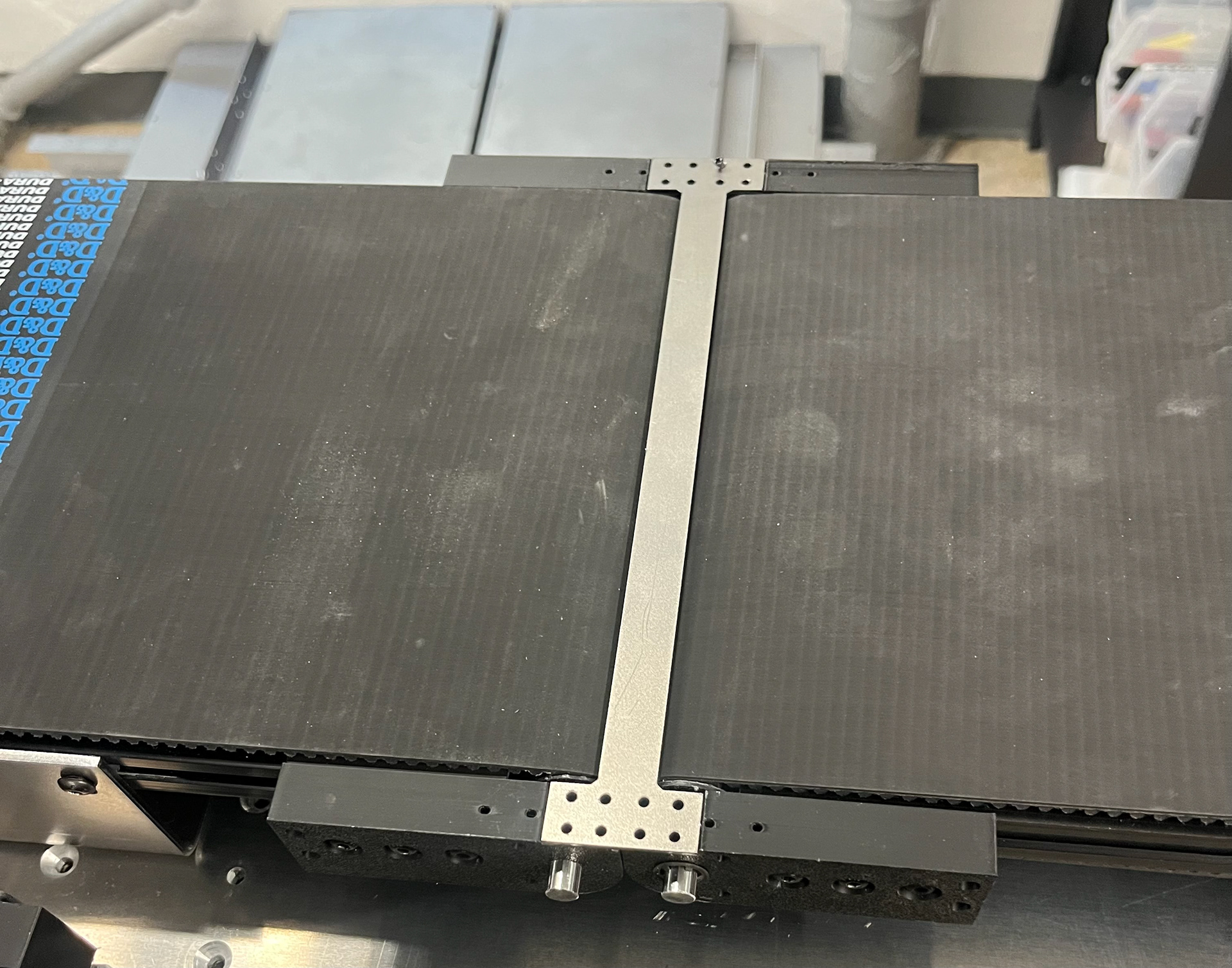

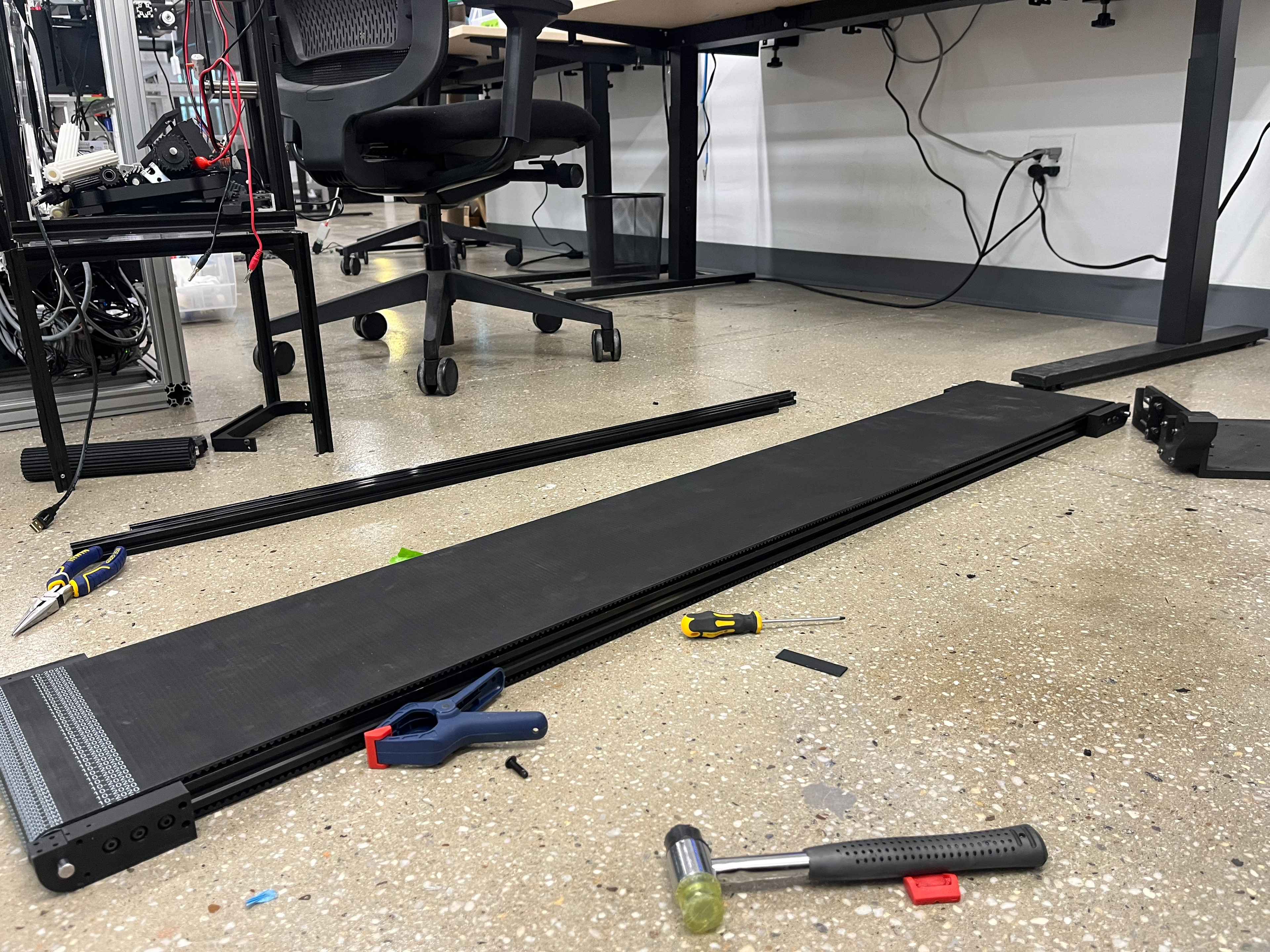

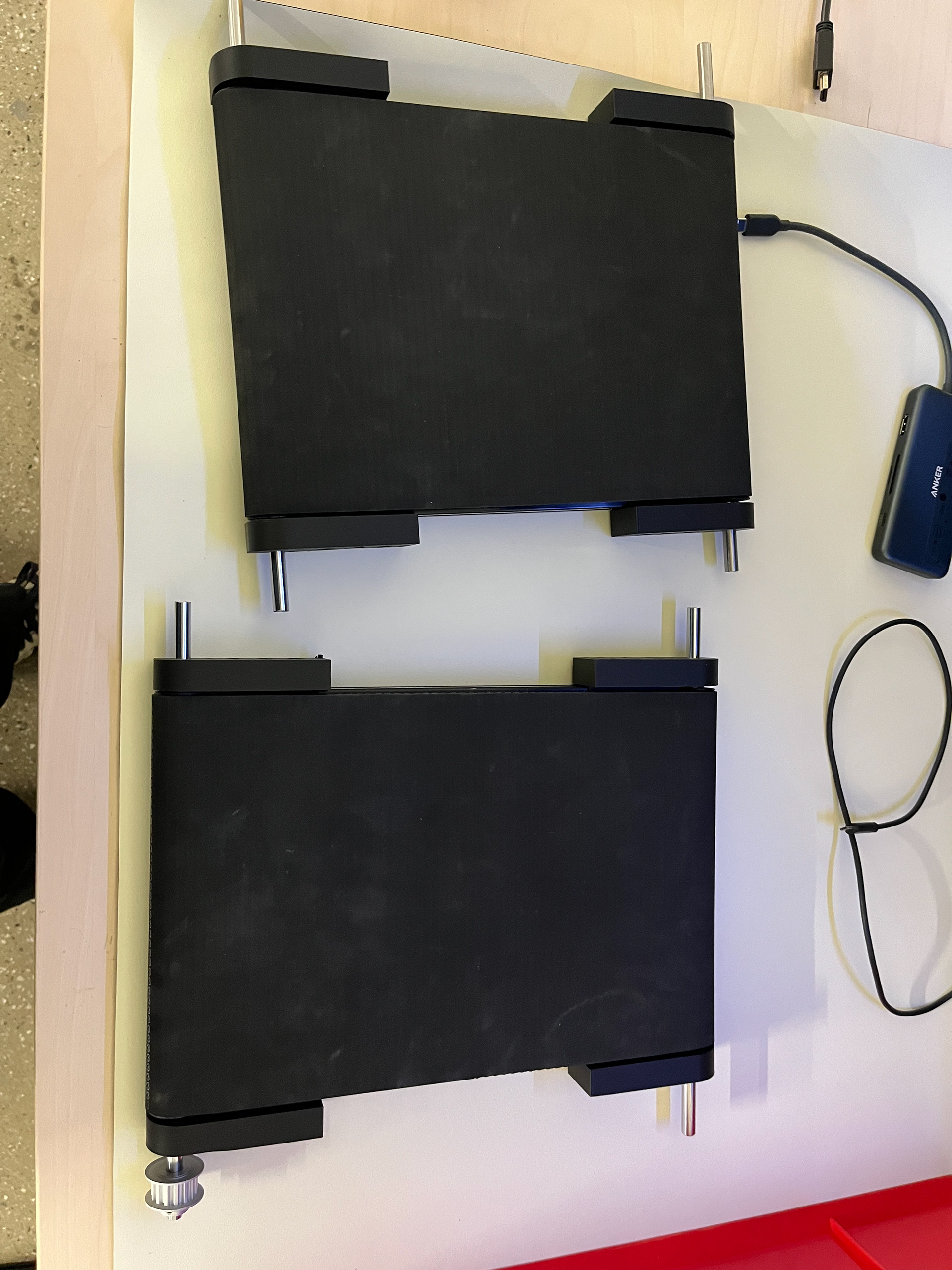

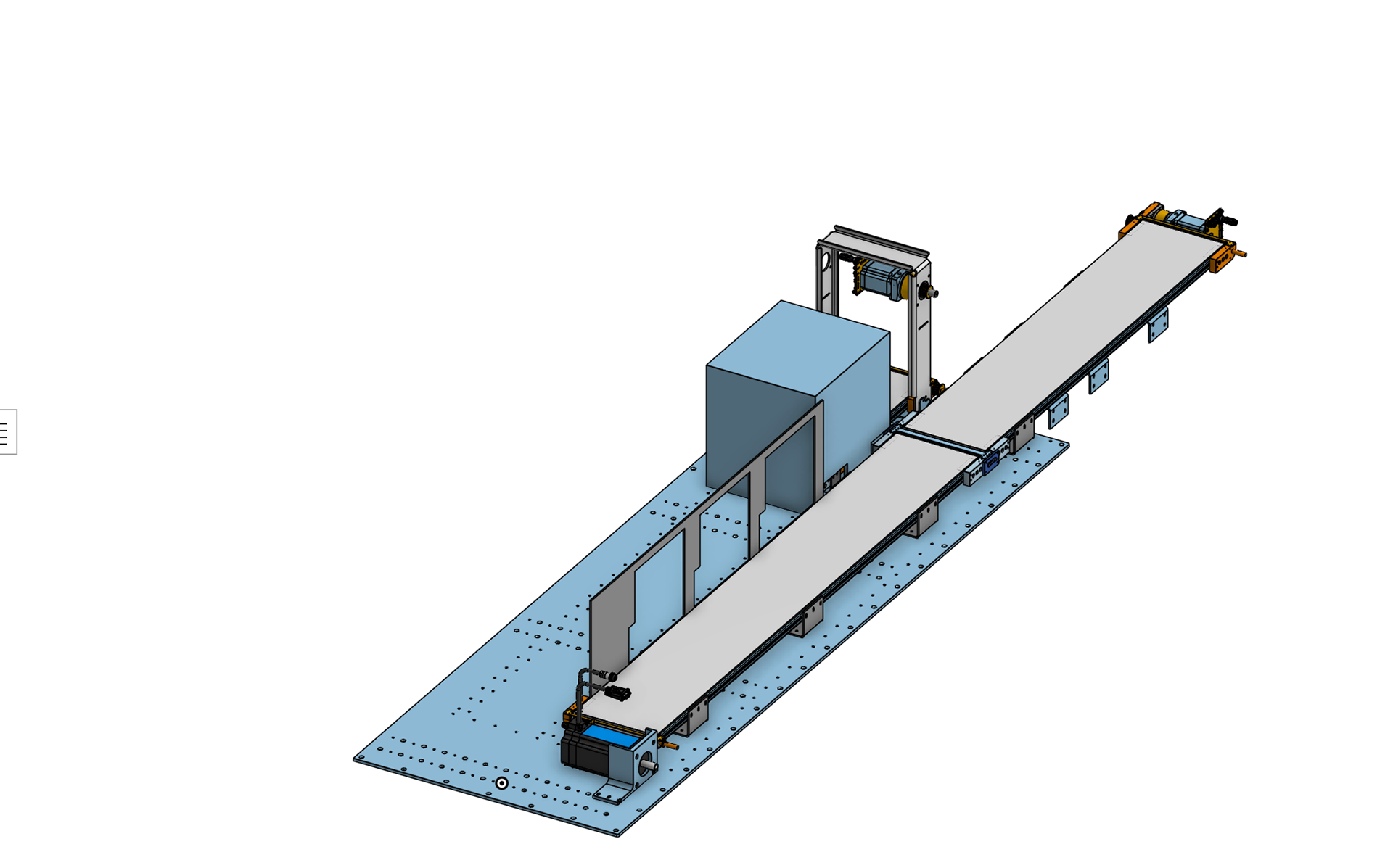

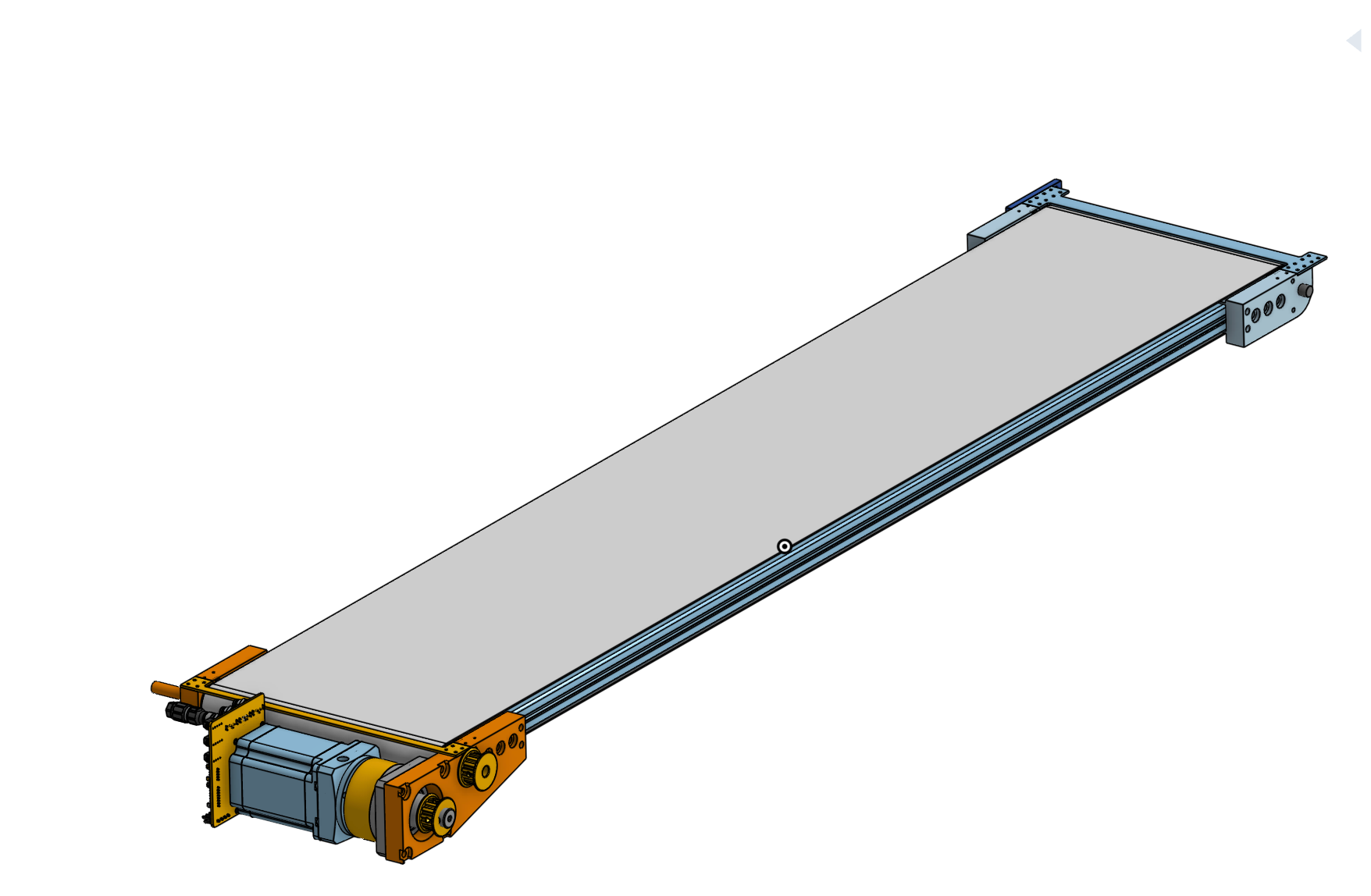

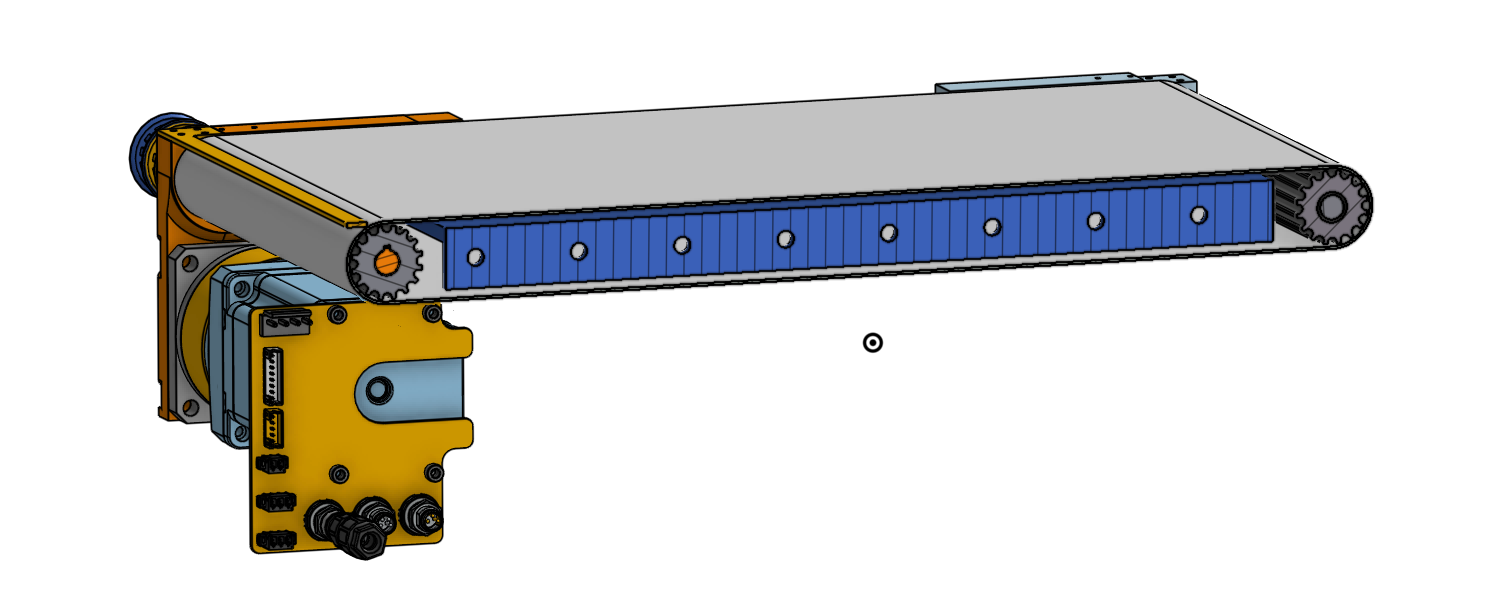

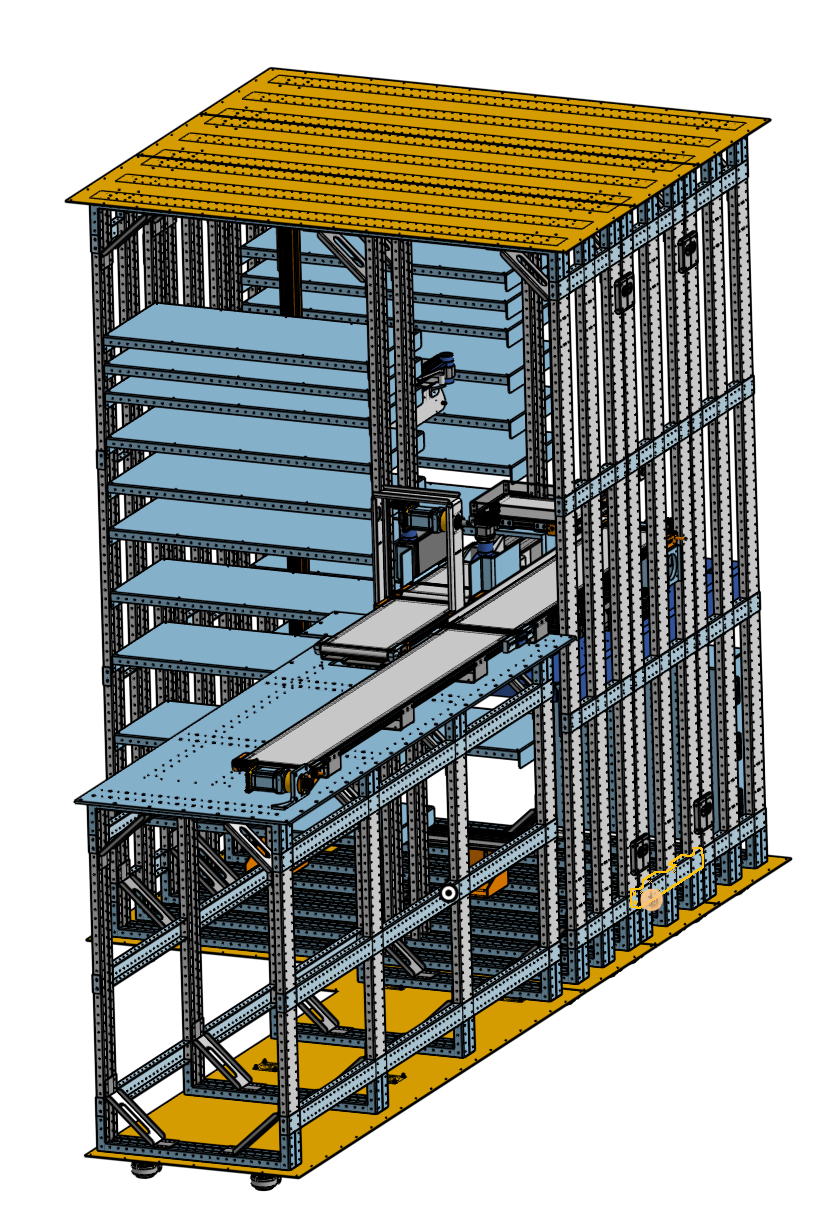

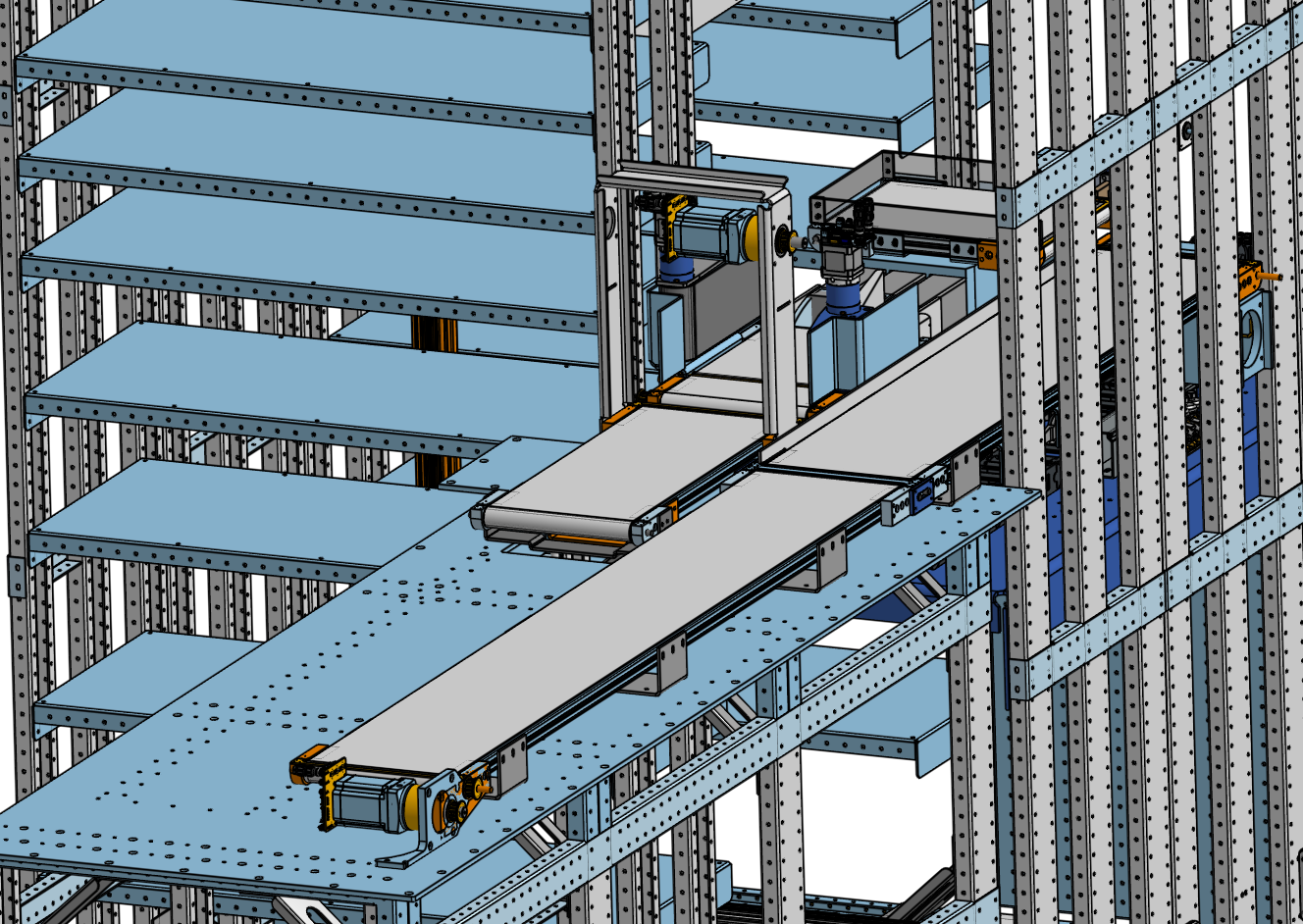

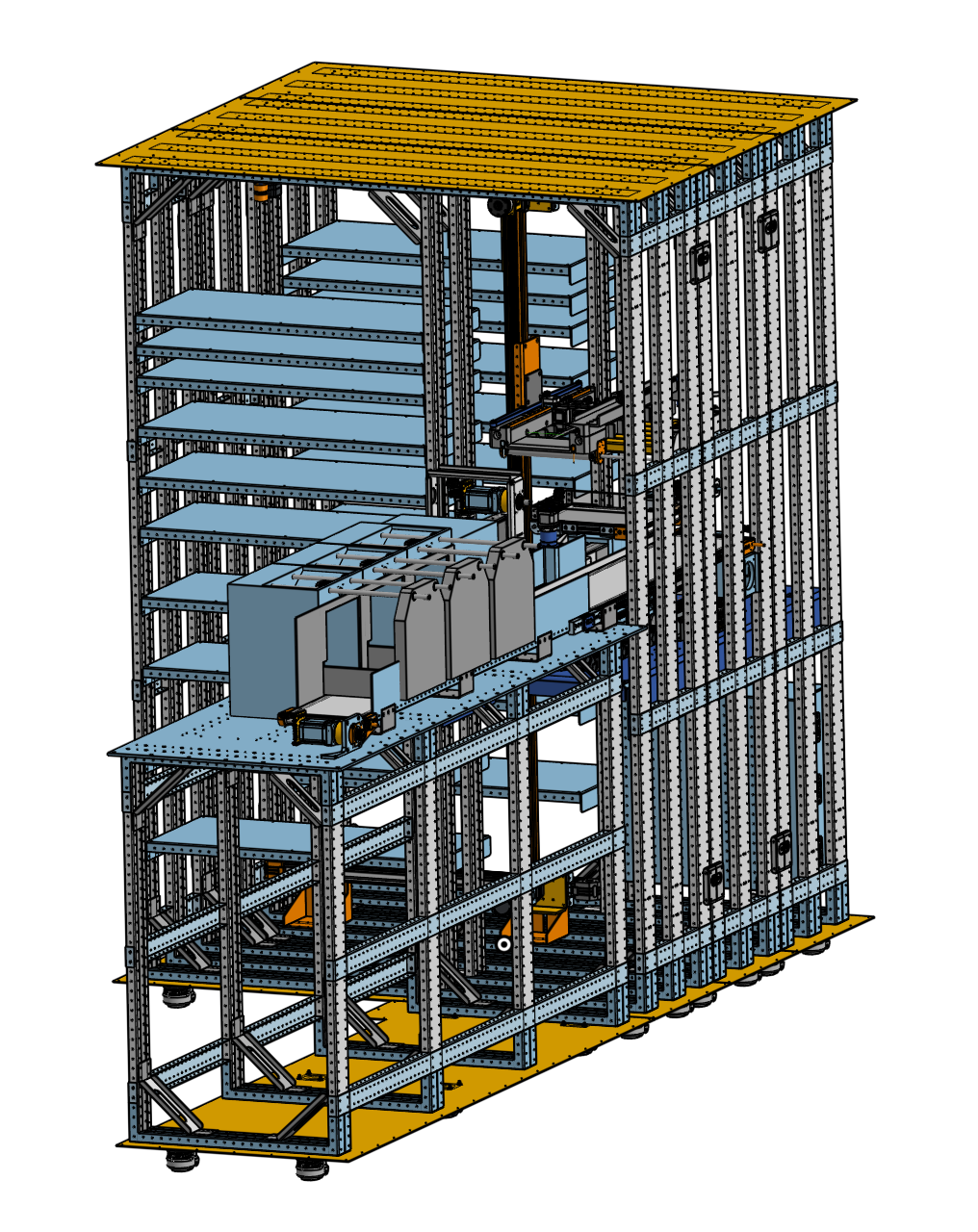

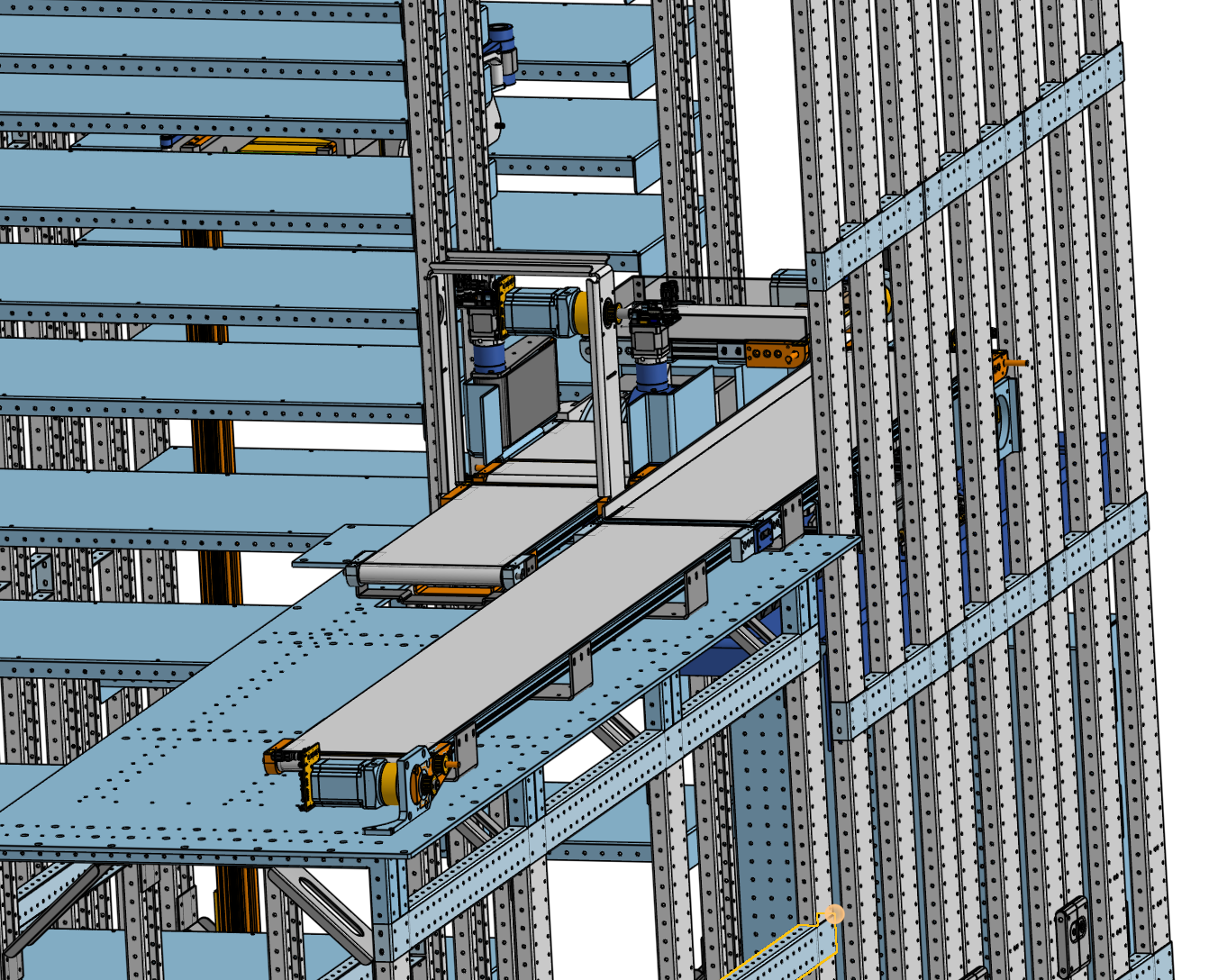

I designed and built five timing pulley-based conveyor belts ranging from 200 mm to 1.5 m in length, used to transport pill bottles within a robotic system and to the end user. These conveyors were created using a parametric CAD model that allowed easy customization of length, width, and motor mount geometry to suit various spatial constraints. Motor mounts were configurable to be above, below at an angle, or inline with the belt. The conveyors were engineered for seamless interfacing with other components—supporting inline transfers, perpendicular transfers, and integration with flat sheet metal bridges for smooth handoffs. The motivation behind this design was to address the limitations of commercially available conveyors, which are often too bulky or poorly suited for handling small pill bottles. Initial designs included “nosebars” for tight transfer radii, but this approach was replaced by using smaller pulleys to reduce height and simplify assembly while maintaining effective performance.